A simple device that can separate plastics that look and feel the same, I owe you an explanation;

The technology to identify plastic is near-infrared spectroscopy. Spectroscopy is the study of the interaction between matter and electromagnetic radiation, near-infrared indicates the wavelength range, so between 750nm to 2500nm.🥼

To help you understand near-infrared spectroscopy, I will give examples where I replace IR light with visible light, this is just a shift in the electromagnetic spectrum. The visible spectrum ranges from 400nm to 750nm.

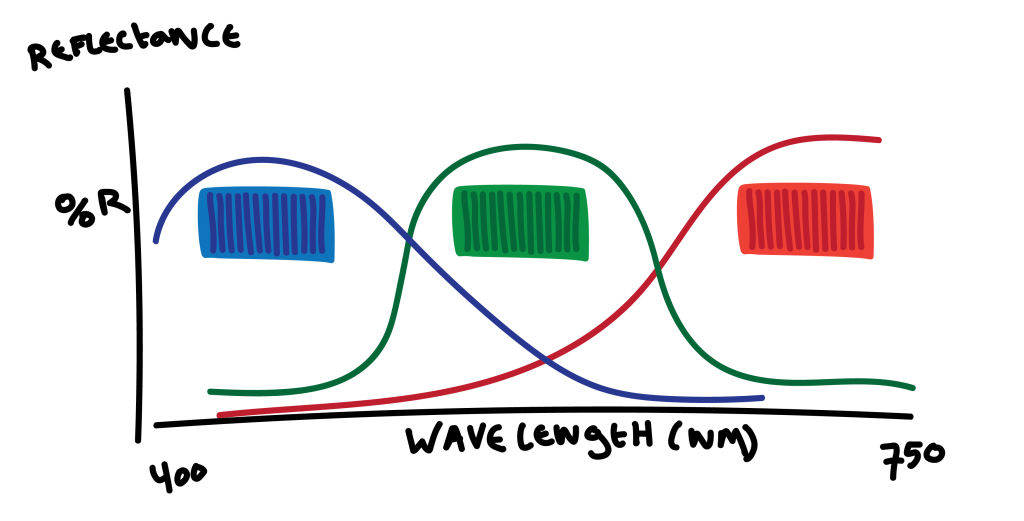

If you see an object, you see it because light is reflected off it into your eye. If you shine white light on an object, all the different wavelengths get absorbed and only the wavelengths of the color of the object are reflected back in your eye. Thus, you can see that an object is orange.

If you replace your eye with a spectroscope in the image above you get different graphs for different colors of bottle caps.

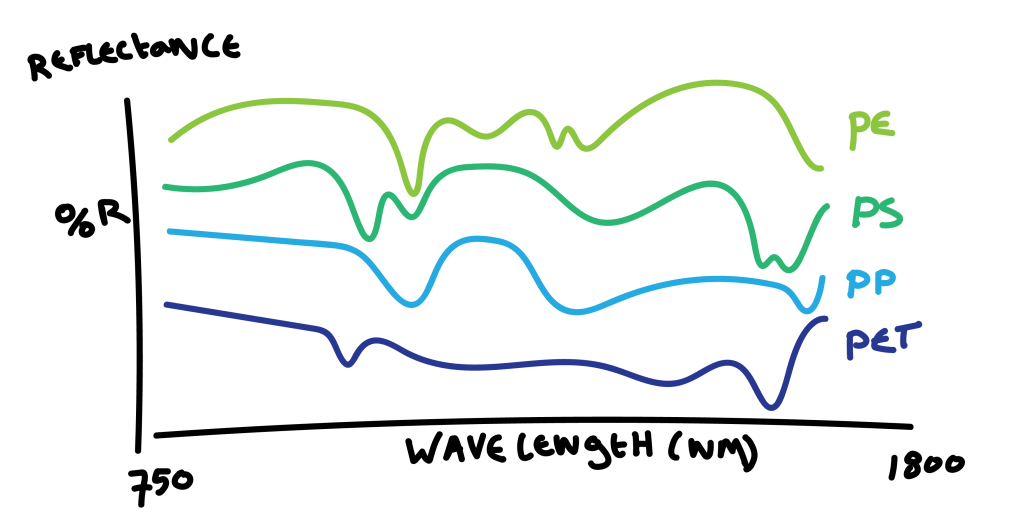

The same can be done with infrared light and plastic objects. If infrared light is shined on a plastic object, some of the wavelengths are absorbed and some are reflected. Different chemical bonds absorbe energy differently, resulting in dips in reflection. Based on this you can start to see the differences between different types of plastic!

At the end of the blog there is a link to more detailed information

Big recycling infrastructure has been using this technology for a while. the spectrum of the plastic waste is collected and based on that sorted, often with compressed air.

Even handheld scanners are available that can identify 30 different types of plastic, like for example this one. A slight downside, these start at 50.000 euro. A 50.000 euro scanner is not viable for plastic recyclers all over the world. for this, the price should go down by around 100 times at least. The most expensive components in these scanners are the optics and the sensors. The mixed infrared light needs to be split into different wavelengths (as a prism does with visible light). The intensity of these different wavelengths is measured individually and gives the reflection chart you can see above. The splitting of the light can be done with traditional optics but also with MEMS sensors. A simplified view of how this is split can be seen in the image below. 🌈

If you look at the reflection curves of the different plastics there are a few distinct dips. Based on that knowledge, Masoumi and Safavi researched to see if they could separate common plastics with just two wavelengths, they made two filters that blocked all wavelengths except 1656nm and 1724nm. based on the ratios between these values they were successful in sorting plastic, hurray!🎉 (link to the paper at the end)

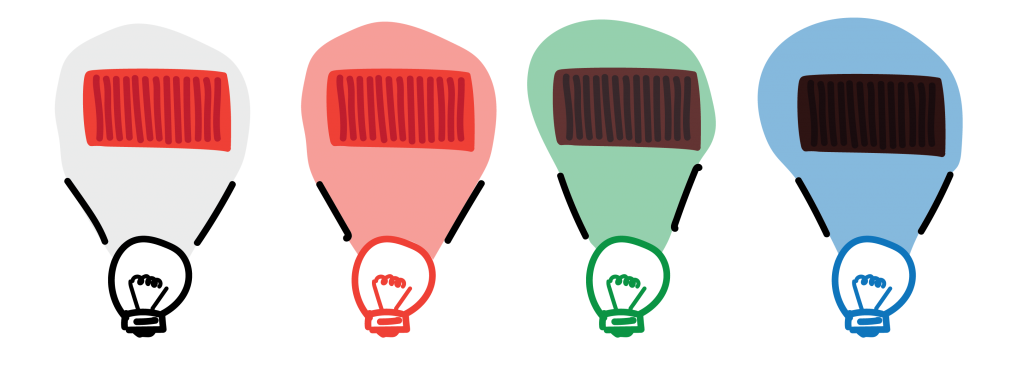

The downside was that they needed very complex and precise filters, still very expensive…. To significantly reduce the price, Straller and Gessler set out to develop a low-cost solution. They basically turned the mechanism upside down, instead of filtering out specific wavelengths, why not send out specific wavelengths. They gathered common IR LEDs with specific wavelengths and used these for reflection measurement.

To give an example with visible light, you can think of it this way: If you shine all wavelengths on an object (white light) it reflects the wavelength of its color(red). If you shine a red light on a red object, the reflection will be very strong, this will be less with green and blue filtered lights.

In order to make the product work, different wavelength LEDs are shine on an object one by one, and each time the intensity of the reflection is measured. NIR LEDs that are easily available are 1650, 1550, 1450, 1300, 1200, 1050, 950, and 850nm. 📈This results in 8 measurement points on the reflection curve, enough to identify the five most common plastics!

Until next time, Jerry ✌

Take a deep dive:

If you liked this blog and you want to read more, here are three links so some great online content.

A general introduction into NIR spectropscopy

Identification of plastics using just two specific NIR wavelengths

Identification of plastic using discrete NIR wavelength LEDs and a single sensor